Types of Electrical Conductors: Understanding Classes 1, 2, 5, and 6 (IEC 60228 Guide)

Electrical

Types of Electrical Conductors – Eyby.com Technical Guide

Conductors used in energy cables are typically manufactured according to the IEC 60228 standard or equivalent national standards derived from it.

Electrical conductors are categorized into four main classes depending on their structure and intended application:

· Class 1 – Solid conductors

· Class 2 – Stranded conductors

· Class 5 – Flexible conductors

· Class 6 – Extra flexible conductors

Class 1: Solid Conductors

These conductors are made from a single round wire, either bare or metal-coated, usually between 0.5 mm² and 16 mm².

They are used primarily in fixed installations where flexibility is not required.

Common Cable Types:

H05V-U, H07V-U, H05Z1-U, H07Z1-U, NVV, YVV, YVCV, YVZ2V, NHXMH, N2XH, N2XCH, N2XRH, YXV, YXCV, YXZ2V (≤ 16 mm²).

Unless otherwise specified, these cables are produced with Class 1 conductors.

Technical Reference:

Maximum DC resistance and conductor diameters are defined in EN 60228 (Table 1 & C.1).

Single-wire diameter can be calculated using the standard formula for resistivity.

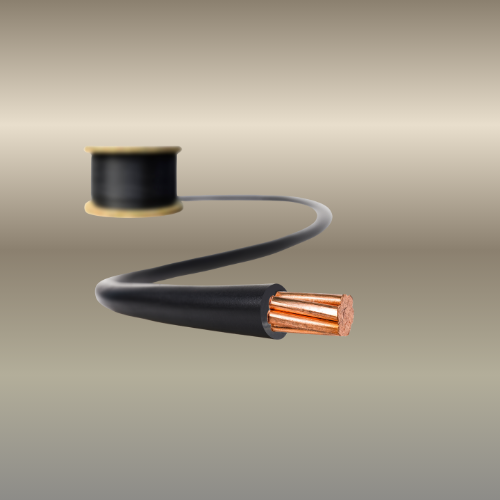

Class 2: Stranded Conductors

Composed of multiple wires twisted together (bare or coated), Class 2 conductors provide moderate flexibility and are available in circular, compacted circular, or sectoral forms.

Available Ranges:

· Circular: 0.5 mm² – 1200 mm²

· Compacted Circular: 16 mm² – 1200 mm²

· Sectoral: 35 mm² – 400 mm²

Common Cable Types:

· Low Voltage (LV): H05V-R, H07V-R, H05Z1-R, H07Z1-R

· Medium/High Voltage (MV/HV): YXC7V-R, YXC8VZ3V-R, YXC7Z1-R, YXC8Z1Z3Z1-R, YE3S(AL)E

Key Properties:

Class 2 conductors meet EN 60228 requirements for:

· Maximum DC resistance

· Minimum number of strands

· Maximum conductor diameter

Class 5 & Class 6: Flexible Conductors

These consist of multiple fine copper strands (bare or coated) and are used in applications requiring bending, movement, or vibration resistance.

Class 5 (Flexible):

Used in installations with low bending radii or moderate motion.

Examples: H05V-K, H07V-K, H05Z1-K, H07Z1-K, H03VV-F, H05VV-F, H05VV5-F, H05VVC4V5-K, H05VVH6-F, H05RR-F, H07RN-F, 052XZI-F

Class 6 (Extra Flexible):

For dynamic or high-motion use (e.g., welding, robotics).

Examples: H01N2-D, H01N2-E

Designation Notes:

· F: Flexible cables approved for moving use

· K: Flexible cables for fixed use only

Key Properties:

Comply with EN 60228 Tables 3 & 4 for DC resistance, strand count, and strand diameter.

Summary Table – Flexibility Classes

|

Class |

Type |

Structure |

Typical Use |

|

1 |

Solid |

Single wire |

Fixed installation |

|

2 |

Stranded |

Multi-wire |

Fixed or semi-flexible |

|

5 |

Flexible |

Fine strands |

Moderate motion |

|

6 |

Extra Flexible |

Very fine strands |

Continuous movement |

Frequently Asked Questions

1. What’s the difference between solid and stranded conductors?

Solid conductors use one solid wire, ideal for fixed systems. Stranded conductors combine several smaller wires for better flexibility and fatigue resistance.

2. Which conductor class is best for flexible applications?

Classes 5 and 6 — Class 5 for moderate movement, Class 6 for continuous or dynamic movement (e.g., robotic systems).

3. What standard defines conductor properties?

IEC 60228, which outlines construction, resistance, and performance requirements.

4. Why is copper preferred over aluminum?

Copper offers higher conductivity, tensile strength, and corrosion resistance, ensuring more efficient current flow.

5. How can I identify conductor class from the cable code?

The letter after the insulation type shows the flexibility class — for instance, “K” = Class 5 (flexible), “F” = Class 6 (extra flexible).

Disclaimer:

The information in this article is intended for general reference. Always verify electrical specifications and installation standards with a certified engineer or relevant regulatory authority before application.