- Home

- Plumbing

- Plumbing Valves

- Shut Off Valves

- Ball Valves

Ball Valves

Ball valves control the flow of chemically compatible media within a system. The ball within the valve body turns to an open and closed position by manual, electric, or pneumatic actuation. Manually-operated ball valves, also known as quarter-turn valves, open and close with a handle to control medi .....Read More

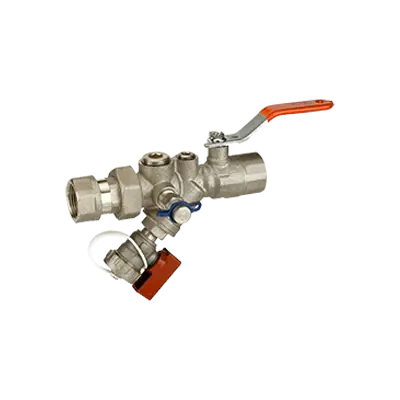

Combination Strainer Ball Valves

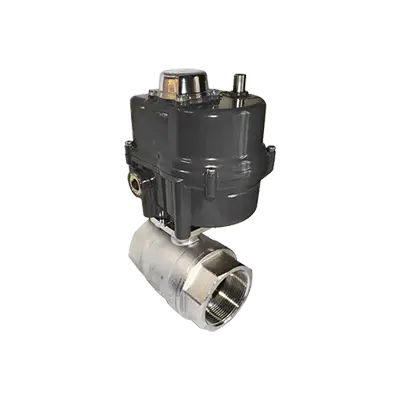

Electrically-Actuated Ball Valves for Chemicals

Fire-Safe Manual Ball Valves

General Purpose Manual Ball Valves

General Purpose Pneumatically-Actuated Ball Valves

Manual Ball Valves for Chemicals

Parts & Accessories for Ball Valves

Pneumatically-Actuated Ball Valves for Potable Water

Frequently Asked Questions

What are the main types of ball valves?

How do you choose between manual, electric, and pneumatic actuation for ball valves?

What materials are ball valves typically made from?

How do you maintain and repair ball valves?

What are the advantages of using ball valves in a system?

How do you determine the correct size of a ball valve for a specific application?

What are common issues or failures associated with ball valves and how can they be prevented?