- Home

- Plumbing

- Plumbing Valves

- Shut Off Valves

- Gate Valves

Gate Valves

Gate valves use a handwheel or lever to raise and lower a gate within the valve body and control the flow of chemically compatible media within a system. General-purpose gate valves control the flow of compatible media in various commercial and industrial applications. Gate valves for potable water .....Read More

Boiler Blow-Off Gate Valves

Brass Gate Valves for Potable Water

Brass General Purpose Gate Valves

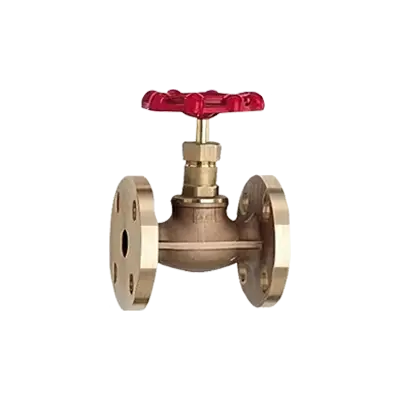

Bronze Gate Valves for Potable Water

Bronze General Purpose Gate Valves

Carbon Steel Gate Valves for Petroleum & Gas Industry

Cast Iron & Ductile Iron General Purpose Gate Valves

CPVC Gate Valves for Chemicals

Gate Valves for Dry Materials

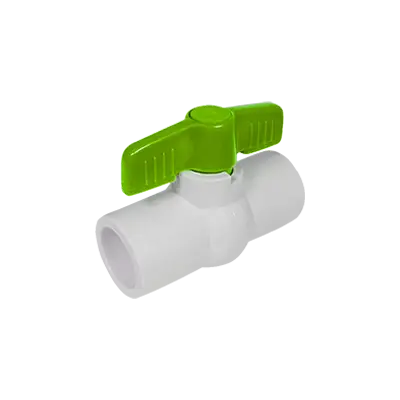

PVC Gate Valves for Chemicals

PVC Gate Valves for Potable Water

PVC General Purpose Gate Valves

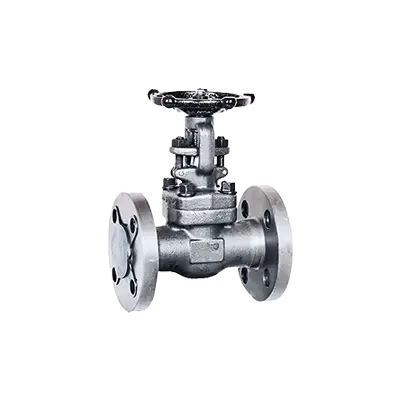

Stainless Steel Gate Valves for Petroleum & Gas Industry

Stainless Steel General Purpose Gate Valves

Valve Stem Guards

Frequently Asked Questions

What is a gate valve and how does it work?

What are the main types of gate valves?

How do you choose the right gate valve for a specific application?

What materials are gate valves typically made from?

How do you maintain and troubleshoot gate valves?

What are the advantages and disadvantages of using gate valves?

How do gate valves compare to other types of valves, such as ball or globe valves?