Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Safety

- Floor Mats

- Static Control Mats

.....Read More

Frequently Asked Questions

What are static-control mats made of?

Static-control mats, also known as anti-static mats, are typically made from materials designed to dissipate static electricity and prevent electrostatic discharge (ESD). These materials include:

1. **Rubber**: Often used for its durability and resistance to chemicals, rubber mats can be either conductive or dissipative. Conductive rubber mats contain carbon or other conductive materials to allow static electricity to flow through the mat and be safely grounded.

2. **Vinyl**: Vinyl mats are popular due to their cost-effectiveness and ease of maintenance. They can be made conductive or static-dissipative by incorporating conductive fibers or additives. Vinyl mats are often used in environments where chemical resistance is important.

3. **Foam**: Foam mats are typically used for their cushioning properties, providing comfort for workers who stand for long periods. They can be layered with conductive or dissipative materials to provide static control.

4. **Polyurethane**: Known for its durability and resistance to wear, polyurethane mats can be made static-dissipative. They are often used in environments where both static control and ergonomic support are needed.

5. **Laminates**: Some static-control mats are made from laminated layers of different materials, combining the benefits of each. For example, a mat might have a conductive rubber base with a dissipative vinyl surface.

These mats are designed to be used in conjunction with grounding cords and other ESD control measures to ensure that static electricity is safely discharged. They are commonly used in electronics manufacturing, repair facilities, and other environments where static-sensitive components are handled.

How do static-control mats prevent static electricity?

Static-control mats prevent static electricity by providing a controlled path for the dissipation of static charges. These mats are made from materials that are either conductive or dissipative. Conductive mats have low electrical resistance, allowing static charges to flow through them easily and be grounded. Dissipative mats have higher resistance than conductive mats but still allow charges to flow at a controlled rate, preventing sudden discharges.

When a person or object with a static charge comes into contact with the mat, the charge is transferred to the mat. The mat is connected to a grounding point, usually through a grounding cord, which safely directs the charge away from the person or object and into the ground. This process neutralizes the static charge, reducing the risk of electrostatic discharge (ESD) that can damage sensitive electronic components.

Static-control mats are often used in environments where ESD-sensitive devices are handled, such as electronics manufacturing, repair facilities, and laboratories. They are typically placed on floors or workbenches to ensure that anyone working in these areas is continuously grounded. By maintaining a low-resistance path to ground, static-control mats help protect both equipment and personnel from the harmful effects of static electricity.

What is the difference between conductive and dissipative mats?

Conductive and dissipative mats are both used to control static electricity, but they differ in their electrical properties and applications.

Conductive Mats:

- Conductive mats have a low electrical resistance, typically less than 1 x 10^6 ohms.

- They allow static electricity to flow quickly across the surface and to a grounding point.

- These mats are made from materials like carbon or metal fibers, which provide a direct path for electricity.

- Conductive mats are ideal for environments where rapid discharge of static electricity is necessary, such as in explosive or highly sensitive electronic environments.

- They are often used in areas where static-sensitive components are handled, ensuring that any static charge is immediately neutralized.

Dissipative Mats:

- Dissipative mats have a higher electrical resistance, usually between 1 x 10^6 and 1 x 10^9 ohms.

- They allow static electricity to flow more slowly and in a controlled manner to a grounding point.

- These mats are made from materials that provide a balance between conductivity and insulation, often incorporating a blend of conductive and non-conductive materials.

- Dissipative mats are suitable for environments where controlled discharge is important to prevent damage to sensitive electronic components.

- They are commonly used in electronic assembly and repair areas, where gradual dissipation of static charges is preferred to prevent sudden discharges that could damage components.

In summary, the main difference lies in their resistance levels and the speed at which they discharge static electricity, with conductive mats providing rapid discharge and dissipative mats offering controlled discharge.

How do you install interlocking static-control mats?

1. **Preparation**: Clear the area where the mats will be installed. Ensure the floor is clean, dry, and free of debris. Measure the space to determine the number of mats needed.

2. **Acclimatization**: Allow the mats to acclimate to the room temperature for at least 24 hours. This helps prevent expansion or contraction after installation.

3. **Layout Planning**: Plan the layout by starting from one corner of the room. This helps in minimizing cuts and ensures a uniform look. Consider the direction of the interlocking edges.

4. **Installation**:

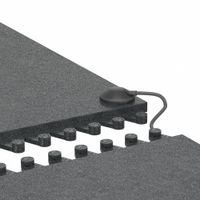

- Begin in a corner, placing the first mat with the interlocking edges facing outwards.

- Connect the next mat by aligning the interlocking edges and pressing them together firmly. Use a rubber mallet if necessary to ensure a tight fit.

- Continue placing mats, working your way across the room. Ensure each mat is securely interlocked with its neighbors.

5. **Cutting**: For edges and corners, measure the required size and mark the mats. Use a utility knife and straight edge to cut the mats to fit. Always cut on the side that will be against the wall to maintain a clean edge.

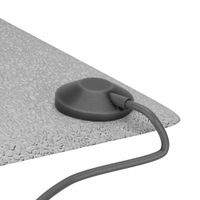

6. **Grounding**: If the mats are designed for static control, ensure they are properly grounded. Connect the grounding cord to the mat and attach it to a grounded outlet or grounding point as per the manufacturer's instructions.

7. **Final Check**: Walk over the entire installation to ensure all mats are securely interlocked and there are no gaps. Adjust as necessary.

8. **Maintenance**: Regularly clean the mats with a damp mop and mild detergent to maintain their static-control properties and appearance. Avoid using harsh chemicals.

Why is grounding important for static-control mats?

Grounding is crucial for static-control mats because it provides a path for static electricity to safely dissipate. Static electricity can accumulate on surfaces and objects, leading to electrostatic discharge (ESD), which can damage sensitive electronic components, disrupt operations, and pose safety hazards. Grounding ensures that any static charge built up on the mat is transferred to the earth, neutralizing the potential for ESD.

Static-control mats are designed to prevent the accumulation of static electricity by being conductive or dissipative. However, without proper grounding, these mats cannot effectively channel the static charge away. Grounding involves connecting the mat to a grounding point, typically using a grounding cord that links the mat to an electrical ground. This connection allows the static charge to flow from the mat to the ground, where it is harmlessly absorbed.

In environments like electronics manufacturing, laboratories, and data centers, where ESD can cause significant damage to equipment and data, grounding static-control mats is essential. It ensures the safety and reliability of operations by protecting sensitive components from ESD-related failures.

Moreover, grounding enhances the effectiveness of static-control mats by maintaining a consistent low-resistance path to ground. This consistency is vital for ensuring that the mats perform their intended function over time, providing ongoing protection against static buildup.

In summary, grounding is a fundamental aspect of using static-control mats, as it ensures the safe and effective dissipation of static electricity, protecting both equipment and personnel from the adverse effects of ESD.

How do you maintain and clean static-control mats?

To maintain and clean static-control mats effectively, follow these steps:

1. **Regular Inspection**: Frequently inspect the mats for wear and tear, ensuring they remain effective in controlling static. Look for signs of damage, such as cuts or abrasions, which can compromise their functionality.

2. **Routine Cleaning**: Clean the mats regularly to maintain their static-control properties. Use a damp mop or cloth with a neutral pH cleaner. Avoid harsh chemicals or abrasive cleaning tools that can damage the mat's surface.

3. **Vacuuming**: For dry cleaning, vacuum the mats to remove dust and debris. Use a vacuum with a HEPA filter to ensure fine particles are effectively captured.

4. **Deep Cleaning**: Periodically, perform a deep clean using a specialized ESD-safe cleaner. Follow the manufacturer's instructions for dilution and application to avoid damaging the mat.

5. **Drying**: After cleaning, ensure the mats are thoroughly dried before use. Excess moisture can affect their performance and lead to mold or mildew growth.

6. **Grounding Check**: Regularly check the grounding connections to ensure they are secure and functioning. A properly grounded mat is essential for effective static control.

7. **Rotation**: If possible, rotate the mats to distribute wear evenly, prolonging their lifespan.

8. **Storage**: When not in use, store the mats flat or rolled (as per manufacturer guidelines) in a clean, dry area to prevent deformation.

9. **Replacement**: Replace mats that show significant wear or damage, as they may no longer provide adequate static protection.

10. **Documentation**: Keep records of maintenance and cleaning schedules to ensure consistent care and identify patterns in wear or damage.

By following these steps, you can maintain the effectiveness and longevity of static-control mats, ensuring a safe and static-free environment.

What industries commonly use static-control mats?

Industries that commonly use static-control mats include:

1. **Electronics Manufacturing**: Static-control mats are crucial in electronics manufacturing to prevent electrostatic discharge (ESD) that can damage sensitive electronic components and circuits during assembly and testing.

2. **Semiconductor Industry**: In semiconductor fabrication, static-control mats are used to protect delicate semiconductor wafers and chips from ESD, which can cause defects and reduce yield.

3. **Telecommunications**: Companies in the telecommunications sector use static-control mats to safeguard equipment and components from static electricity, ensuring reliable performance and longevity.

4. **Aerospace**: The aerospace industry employs static-control mats to protect avionics and other sensitive electronic systems from ESD, which is critical for safety and functionality.

5. **Automotive**: Automotive manufacturers use static-control mats in the production of electronic control units (ECUs) and other electronic components to prevent ESD-related failures.

6. **Medical Device Manufacturing**: Static-control mats are used in the production of medical devices to protect sensitive electronic components and ensure the reliability and safety of the devices.

7. **Pharmaceuticals**: In pharmaceutical manufacturing, static-control mats help prevent static electricity from affecting sensitive equipment and processes, ensuring product quality and safety.

8. **Defense and Military**: The defense sector uses static-control mats to protect critical electronic systems and components from ESD, which is vital for mission-critical operations.

9. **Data Centers**: Data centers use static-control mats to protect servers and networking equipment from static discharge, which can cause data loss or hardware damage.

10. **Research and Development**: Laboratories and R&D facilities use static-control mats to protect sensitive instruments and experiments from the effects of static electricity.

These industries rely on static-control mats to maintain product quality, ensure safety, and prevent costly damage to sensitive electronic components and systems.