Call +(254) 703 030 000 / 751 483 999 / 721 704 777

.....Read More

Frequently Asked Questions

What is the purpose of Lockout/Tagout (LOTO) procedures?

The purpose of Lockout/Tagout (LOTO) procedures is to ensure the safety of workers by preventing the accidental or unexpected energization or release of hazardous energy during the maintenance and servicing of machinery and equipment. LOTO procedures are critical in safeguarding employees from risks associated with electrical, mechanical, hydraulic, pneumatic, chemical, thermal, and other energy sources that could cause injury or death.

Key objectives of LOTO procedures include:

1. **Isolation of Energy Sources**: LOTO ensures that all energy sources are identified and isolated before any maintenance or servicing work begins. This involves shutting down equipment and using lockout devices to physically lock the energy-isolating devices in a safe or "off" position.

2. **Prevention of Accidental Start-Up**: By locking out energy sources, LOTO procedures prevent the accidental start-up of machinery, which could lead to serious injuries or fatalities.

3. **Communication and Awareness**: Tagout devices, which are warning tags attached to the locked-out equipment, communicate to all employees that the equipment is under maintenance and should not be operated. This enhances awareness and prevents unauthorized or accidental re-energization.

4. **Standardization and Compliance**: LOTO procedures provide a standardized approach to controlling hazardous energy, ensuring compliance with occupational safety regulations such as OSHA's Control of Hazardous Energy (Lockout/Tagout) standard (29 CFR 1910.147) in the United States.

5. **Protection of Maintenance Personnel**: By following LOTO procedures, maintenance personnel are protected from unexpected energy releases, reducing the risk of injuries such as electrocution, burns, cuts, and crushing.

Overall, LOTO procedures are a critical component of workplace safety programs, aiming to protect workers, reduce accidents, and ensure a safe working environment during equipment maintenance and servicing activities.

How do you properly install a lockout device on machinery?

To properly install a lockout device on machinery, follow these steps:

1. **Preparation**: Identify all energy sources associated with the machinery, including electrical, hydraulic, pneumatic, mechanical, and thermal. Review the machine's manual for specific lockout procedures.

2. **Notify Affected Employees**: Inform all employees who might be affected by the lockout process about the maintenance or servicing work and the need for lockout.

3. **Shutdown Machinery**: Turn off the machinery using the normal stopping procedure (e.g., press the stop button, switch off the power).

4. **Isolate Energy Sources**: Disconnect or isolate all energy sources. This may involve turning off circuit breakers, closing valves, or disconnecting power cords.

5. **Apply Lockout Devices**: Attach lockout devices to each energy-isolating device. Use a lock that is durable and standardized, ensuring it cannot be removed without a key or combination. Each worker should apply their own lock to the lockout device.

6. **Release Stored Energy**: Safely release or restrain any stored energy, such as discharging capacitors, bleeding hydraulic lines, or securing moving parts.

7. **Verify Isolation**: Before starting work, verify that the machinery is properly isolated. Attempt to start the machine using the normal controls to ensure it does not operate.

8. **Perform Maintenance or Servicing**: Conduct the necessary maintenance or servicing work on the machinery.

9. **Remove Lockout Devices**: Once work is complete, ensure all tools and personnel are clear from the area. Each worker should remove their own lock. Restore energy sources in the reverse order of isolation.

10. **Notify Employees**: Inform affected employees that the lockout has been removed and the machinery is ready for use.

11. **Restart Machinery**: Follow the standard operating procedure to restart the machinery safely.

What are the key components of a LOTO program?

The key components of a Lockout/Tagout (LOTO) program are:

1. **Energy Control Procedures**: Detailed instructions for shutting down, isolating, blocking, and securing machines or equipment to control hazardous energy. These procedures must be specific to each piece of equipment and include steps for applying and removing lockout/tagout devices.

2. **Lockout/Tagout Devices**: Physical devices used to lock or tag equipment to prevent accidental energization. Locks are used to physically secure energy-isolating devices, while tags provide a warning and information about the lockout.

3. **Employee Training**: Comprehensive training for all employees involved in or affected by LOTO procedures. This includes training for authorized employees who perform lockout/tagout, affected employees who operate or use the equipment, and other employees who may be in the area.

4. **Periodic Inspections**: Regular inspections of energy control procedures to ensure they are being followed correctly and remain effective. Inspections should be conducted at least annually and involve a review of each procedure and employee performance.

5. **Communication**: Clear communication protocols to inform all affected employees about the lockout/tagout process, including when it is safe to resume work. This includes using standardized tags and labels to convey information.

6. **Documentation**: Maintaining records of all lockout/tagout procedures, training sessions, and inspections. Documentation ensures compliance with regulations and provides a reference for continuous improvement.

7. **Roles and Responsibilities**: Clearly defined roles for authorized, affected, and other employees involved in the LOTO process. This includes assigning responsibility for implementing and enforcing the program.

8. **Program Review and Updates**: Regular review and updating of the LOTO program to incorporate new equipment, changes in procedures, or updates in regulations. This ensures the program remains effective and compliant with safety standards.

How does a lockout padlock function in a LOTO system?

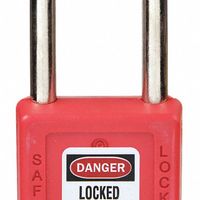

A lockout padlock is a critical component in a Lockout/Tagout (LOTO) system, which is designed to ensure the safety of workers by preventing the accidental energization of machinery or equipment during maintenance or repair. The lockout padlock functions as a physical barrier that secures energy-isolating devices in an off or safe position, ensuring that machinery cannot be activated until the lock is removed.

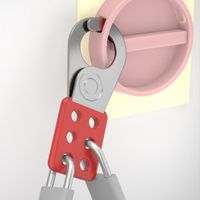

When implementing a LOTO procedure, the first step is to identify all energy sources associated with the equipment. Once identified, the energy-isolating devices, such as circuit breakers, valves, or switches, are turned off or disconnected. The lockout padlock is then applied to these devices, often in conjunction with a lockout hasp or other locking mechanism, to physically prevent them from being reactivated.

Each worker involved in the maintenance or repair process applies their own lockout padlock, ensuring that the equipment cannot be re-energized until all locks are removed. This is crucial for worker safety, as it ensures that no single individual can inadvertently restore power while others are still working on the equipment.

The lockout padlock is typically designed with a unique key or combination, ensuring that only the individual who applied the lock can remove it. This prevents unauthorized removal and ensures that the lockout process is controlled and secure. Additionally, lockout padlocks are often brightly colored and labeled with the worker's name or identification, providing clear visual indication of who is responsible for the lockout.

In summary, the lockout padlock is an essential tool in a LOTO system, providing a secure and controlled method to prevent accidental equipment activation, thereby protecting workers from potential hazards.

What types of equipment require specific LOTO devices?

Lockout/Tagout (LOTO) devices are essential for ensuring the safety of workers during the maintenance and servicing of machinery and equipment. Specific types of equipment that require LOTO devices include:

1. **Electrical Equipment**: Circuit breakers, electrical panels, and switchgear require LOTO devices to prevent accidental energization. Devices like circuit breaker lockouts and plug lockouts are used.

2. **Pneumatic and Hydraulic Systems**: These systems need valve lockouts to secure energy isolation points, preventing the release of stored energy.

3. **Mechanical Equipment**: Machines with moving parts, such as conveyors, presses, and mixers, require mechanical lockout devices to prevent accidental start-up.

4. **Valves**: Ball valves, gate valves, and butterfly valves in fluid systems require valve lockout devices to ensure they remain in the off position.

5. **Compressed Gas Cylinders**: Lockout devices are used to secure the valve handles of gas cylinders to prevent accidental release of gas.

6. **Heavy Machinery**: Equipment like forklifts, cranes, and loaders require LOTO devices to ensure they are not operated during maintenance.

7. **Conveyors**: Conveyor systems require specific lockout devices to prevent accidental movement during servicing.

8. **Boilers and Pressure Vessels**: These require lockout devices to isolate energy sources and prevent accidental pressure build-up.

9. **HVAC Systems**: Heating, ventilation, and air conditioning systems require LOTO devices to ensure safe maintenance.

10. **Chemical Processing Equipment**: Lockout devices are used to secure valves and controls to prevent accidental chemical release.

11. **Robotic Systems**: Robots and automated systems require LOTO devices to prevent accidental activation during maintenance.

12. **Elevators and Escalators**: These require specific lockout devices to ensure they are not operational during servicing.

Each type of equipment may require different LOTO devices tailored to its specific energy sources and operational hazards.

How do cable lockouts work for multiple energy sources?

Cable lockouts are versatile devices used to secure multiple energy sources simultaneously, ensuring that machinery or equipment remains in a safe, de-energized state during maintenance or repair. They work by using a flexible cable, typically made of steel or nylon, which can be threaded through various isolation points on equipment, such as valve handles, circuit breaker toggles, or electrical disconnects.

To use a cable lockout for multiple energy sources, follow these steps:

1. **Identify Energy Sources**: Determine all the energy sources that need to be isolated, including electrical, hydraulic, pneumatic, and mechanical.

2. **Thread the Cable**: Insert the cable through the lockout points of each energy source. This may involve looping the cable through handles, levers, or other components that control the energy flow.

3. **Tighten the Cable**: Pull the cable taut to ensure that all components are securely immobilized. This prevents any accidental re-energization of the equipment.

4. **Secure the Cable**: Once the cable is tight, insert it into the lockout device's body. The device typically has a locking mechanism that holds the cable in place.

5. **Apply a Padlock**: Insert a padlock through the designated hole in the lockout device. This padlock is usually keyed or combination-based, ensuring that only authorized personnel can remove it.

6. **Tag the Lockout**: Attach a tag to the lockout device indicating the reason for the lockout, the person responsible, and the date. This provides clear communication to all personnel involved.

By using a cable lockout, multiple energy sources can be effectively isolated with a single device, enhancing safety and compliance with lockout/tagout procedures.

What is the role of lockout hasps and group lockout boxes?

Lockout hasps and group lockout boxes are critical components in the lockout/tagout (LOTO) safety procedures used to ensure that machines and equipment are properly shut off and not started up again before the completion of maintenance or servicing work.

Lockout hasps are devices that allow multiple padlocks to be used when isolating a single energy source. They are designed to accommodate several workers, each of whom can attach their own padlock to the hasp. This ensures that the energy source cannot be re-energized until all workers have removed their locks, thereby guaranteeing that the equipment remains inoperative while maintenance is being performed. The hasp is placed through the isolating point, and each worker attaches a padlock, ensuring that the equipment cannot be operated until all locks are removed.

Group lockout boxes, on the other hand, are used when multiple energy sources need to be isolated, or when a large team is involved in the maintenance process. In this system, a single lock is placed on each energy isolation point, and the keys to these locks are placed inside a lockout box. Each worker then places their personal lock on the group lockout box. This ensures that the box cannot be opened, and the keys cannot be accessed until every worker has removed their lock. This method simplifies the lockout process by reducing the number of locks needed on each energy source and provides a clear visual indication of the lockout status.

Both lockout hasps and group lockout boxes are essential for ensuring worker safety by preventing accidental machine start-up, thereby reducing the risk of injury during maintenance activities.

How are tagout tags used in a LOTO procedure?

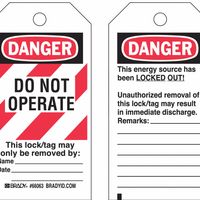

In a Lockout/Tagout (LOTO) procedure, tagout tags are used as a critical safety measure to prevent accidental or unauthorized energization of equipment during maintenance or servicing. These tags serve as a visual warning and communication tool, indicating that the equipment is isolated and should not be operated until the tag is removed by the authorized personnel.

The process begins with the identification of all energy sources associated with the equipment. Once identified, the equipment is turned off and isolated from its energy sources. Lockout devices are applied to energy-isolating devices to ensure they remain in a safe or off position. If a lock cannot be applied, a tagout system is used.

Tagout tags are attached to the energy-isolating devices, such as switches, valves, or circuit breakers, using a durable, non-reusable attachment method. The tags must be clearly visible and legible, displaying information such as the name of the person who applied the tag, the date, and the reason for the lockout. This ensures that anyone approaching the equipment is aware of the maintenance work being performed and the potential hazards.

The tags must be standardized in terms of color, shape, and size to ensure they are easily recognizable. They should be made of materials that can withstand environmental conditions such as moisture, chemicals, and temperature variations.

Only the person who applied the tag is authorized to remove it, ensuring accountability and preventing premature re-energization. Before removing the tag, the authorized person must ensure that all tools and personnel are clear from the equipment, and that it is safe to restore energy.

In summary, tagout tags are an essential component of the LOTO procedure, providing a clear and effective means of communication to enhance safety during equipment maintenance.

What are the OSHA requirements for LOTO compliance?

OSHA's Lockout/Tagout (LOTO) standard, found in 29 CFR 1910.147, outlines specific requirements to control hazardous energy during the servicing and maintenance of machines and equipment. Key requirements include:

1. **Energy Control Program**: Employers must establish a program consisting of energy control procedures, employee training, and periodic inspections to ensure machines are properly isolated from energy sources.

2. **Energy Control Procedures**: Develop, document, and use procedures for controlling hazardous energy. These procedures must detail the scope, purpose, authorization, rules, and techniques to be used for LOTO, including specific steps for shutting down, isolating, blocking, and securing machines.

3. **Lockout/Tagout Devices**: Use lockout devices for energy isolation. If lockout is not possible, tagout devices may be used, but they must provide equivalent protection. Devices must be durable, standardized, and substantial.

4. **Employee Training**: Train employees on the energy control program. Authorized employees must be trained on recognizing hazardous energy sources and the methods for energy isolation and control. Affected employees need to understand the purpose and use of energy control procedures.

5. **Periodic Inspections**: Conduct annual inspections of energy control procedures to ensure compliance and effectiveness. Inspections must be performed by an authorized employee not involved in the procedure being inspected.

6. **Communication and Coordination**: Ensure clear communication and coordination among all employees involved in LOTO procedures, especially during shift changes or when multiple employers are involved.

7. **Documentation and Recordkeeping**: Maintain records of training, inspections, and any incidents related to LOTO to ensure ongoing compliance and improvement of safety practices.

These requirements aim to prevent accidental machine start-up or release of stored energy, thereby protecting workers from injuries.

How can LOTO stations and kits improve safety and organization?

LOTO (Lockout/Tagout) stations and kits significantly enhance safety and organization in industrial and maintenance environments by providing a systematic approach to controlling hazardous energy. These tools ensure that machinery and equipment are properly shut off and not started up again before the completion of maintenance or servicing work.

1. **Safety Enhancement**: LOTO stations and kits prevent accidental machine start-ups, which can lead to severe injuries or fatalities. By using locks, tags, and other devices, they ensure that only authorized personnel can remove them, maintaining control over the equipment's energy sources. This process is crucial in protecting workers from unexpected energization or release of stored energy.

2. **Compliance with Regulations**: Implementing LOTO procedures helps organizations comply with safety regulations such as OSHA standards in the United States. Compliance not only avoids legal penalties but also promotes a culture of safety within the workplace.

3. **Centralized Access**: LOTO stations provide a centralized location for all lockout/tagout devices, making it easier for workers to access the necessary tools quickly. This organization reduces downtime and ensures that the correct devices are used for specific equipment, enhancing efficiency and safety.

4. **Standardization**: LOTO kits standardize the lockout/tagout process across the organization. By having a consistent set of tools and procedures, workers are better trained and more familiar with the safety protocols, reducing the likelihood of errors.

5. **Visual Management**: The use of tags and labels in LOTO kits provides clear visual warnings and information about the status of equipment, which helps in communicating potential hazards to all employees, even those not directly involved in the maintenance work.

Overall, LOTO stations and kits are essential for maintaining a safe and organized work environment, protecting workers, and ensuring operational efficiency.