Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Safety

- Signs Facility Identification Products

- Utility Location Marking

.....Read More

Frequently Asked Questions

What are utility marking products used for?

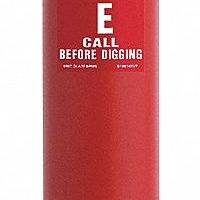

Utility marking products are used to identify and delineate the location of underground utilities such as water, gas, electricity, telecommunications, and sewer lines. These markings are crucial for preventing damage during excavation or construction activities. By clearly indicating where these utilities are located, workers can avoid accidental strikes that could lead to service disruptions, costly repairs, or even hazardous situations.

The markings are typically applied using paint, flags, or stakes, each color-coded according to a standardized system to represent different types of utilities. For example, red is often used for electric power lines, yellow for gas, oil, or steam, blue for potable water, green for sewer and drain lines, orange for communication lines, and purple for reclaimed water.

Utility marking products are essential for compliance with safety regulations and standards, such as those set by the Occupational Safety and Health Administration (OSHA) and the Common Ground Alliance (CGA). They help ensure that all parties involved in a project are aware of the underground infrastructure, thereby reducing the risk of accidents and enhancing overall safety.

In addition to safety, these products also facilitate efficient project planning and execution. By providing a clear visual guide to the location of utilities, they help in the accurate mapping and documentation of underground assets, which is vital for future maintenance and development projects.

Overall, utility marking products play a critical role in safeguarding infrastructure, protecting workers, and ensuring the smooth operation of essential services.

How do you choose the right utility marking product for a specific application?

To choose the right utility marking product for a specific application, consider the following factors:

1. **Surface Type**: Identify the surface where the marking will be applied, such as asphalt, concrete, grass, or dirt. Different surfaces may require specific types of marking products for optimal adhesion and visibility.

2. **Environmental Conditions**: Assess the environmental conditions, including weather, temperature, and exposure to sunlight or moisture. Some products are designed to withstand harsh weather, while others may fade or wash away.

3. **Duration of Marking**: Determine the required longevity of the marking. Temporary projects may only need short-term visibility, while permanent installations require durable, long-lasting products.

4. **Visibility Requirements**: Consider the visibility needs, such as color contrast and reflectivity, especially in low-light conditions. High-visibility colors and reflective options enhance safety and effectiveness.

5. **Regulatory Compliance**: Ensure the product meets any local, state, or federal regulations regarding utility marking, including color codes and material specifications.

6. **Application Method**: Evaluate the ease of application and the tools required. Some products are available in spray cans for quick application, while others may need specialized equipment.

7. **Cost and Budget**: Balance the cost of the product with the project budget. While cheaper options may be tempting, they might not offer the durability or visibility required.

8. **Safety and Environmental Impact**: Consider the safety of the product for workers and the environment. Non-toxic, eco-friendly options are preferable for minimizing health risks and environmental damage.

9. **Brand Reputation and Reviews**: Research brands and read reviews to gauge product reliability and customer satisfaction.

By carefully evaluating these factors, you can select the most appropriate utility marking product for your specific application, ensuring effectiveness, compliance, and safety.

What do the different colors of utility marking flags and tapes signify?

Utility marking flags and tapes are color-coded to indicate the type of underground utility lines present in an area. This standardized color system helps prevent damage during excavation and construction activities. Here are the colors and their meanings:

1. **Red**: Electric power lines, cables, conduit, and lighting cables. Red indicates danger and is used for high-voltage lines.

2. **Yellow**: Gas, oil, steam, petroleum, or other gaseous materials. Yellow signifies caution due to the flammable nature of these utilities.

3. **Orange**: Communication, alarm or signal lines, cables, or conduit. This includes telephone, cable TV, and fiber optics.

4. **Blue**: Potable water. Blue is associated with water lines that are safe for drinking.

5. **Green**: Sewers and drain lines. Green is used for wastewater and stormwater systems.

6. **Purple**: Reclaimed water, irrigation, and slurry lines. Purple indicates non-potable water sources.

7. **White**: Proposed excavation sites. White markings are used to outline the area where digging will occur.

8. **Pink**: Temporary survey markings. Pink is used by surveyors to mark legal property boundaries and other survey-related information.

These colors are part of the American Public Works Association (APWA) Uniform Color Code, which is widely adopted in the United States. The system helps ensure safety and efficiency by clearly identifying the type of utility lines present, reducing the risk of accidents and service interruptions.

How are utility marking posts installed?

Utility marking posts are installed through a series of steps to ensure accurate and safe placement. First, a site survey is conducted to identify the exact location of underground utilities such as gas, water, electricity, and telecommunications lines. This is often done using maps, ground-penetrating radar, or electromagnetic equipment.

Once the utilities are located, the area is marked with temporary paint or flags to indicate where the posts will be installed. The next step involves selecting the appropriate type of marking post, which can vary based on the utility type and environmental conditions. Common materials include fiberglass, plastic, or metal, each chosen for durability and visibility.

The installation process begins by digging a hole at the marked location. The depth and width of the hole depend on the size of the post and soil conditions, but it typically ranges from 18 to 36 inches deep. The post is then placed into the hole, ensuring it is upright and aligned correctly. For added stability, the hole is backfilled with soil or concrete, which is compacted to secure the post in place.

After installation, the post is often labeled with information such as the type of utility, contact numbers for emergencies, and any relevant safety warnings. This labeling is crucial for maintenance crews and the public to identify the utility type and take necessary precautions.

Finally, a quality check is performed to ensure the post is visible, stable, and correctly labeled. Regular maintenance checks are scheduled to ensure the post remains in good condition and continues to serve its purpose effectively.

What materials are utility marking products typically made from?

Utility marking products are typically made from a variety of materials designed to withstand environmental conditions and provide clear visibility. Common materials include:

1. **Plastic**: High-density polyethylene (HDPE) and polypropylene are frequently used for marker posts and flags due to their durability, flexibility, and resistance to UV rays and chemicals.

2. **Fiberglass**: Used for marker posts and stakes, fiberglass is lightweight, strong, and resistant to corrosion, making it ideal for long-term outdoor use.

3. **Metal**: Aluminum and galvanized steel are used for signs and markers due to their strength and resistance to rust. Aluminum is lightweight and corrosion-resistant, while galvanized steel offers enhanced durability.

4. **Vinyl**: Used for marking tapes and labels, vinyl is flexible, weather-resistant, and can be printed with bright, visible colors.

5. **Paint**: Temporary marking paints are often made from water-based or solvent-based formulations that adhere well to surfaces like asphalt, concrete, and grass. They are designed to be highly visible and may be fluorescent for enhanced visibility.

6. **Reflective Materials**: Reflective films or coatings are applied to markers and signs to improve visibility in low-light conditions. These materials often incorporate glass beads or prismatic technology.

7. **Biodegradable Materials**: For temporary markings, biodegradable flags and tapes are used to minimize environmental impact. These materials break down over time, reducing waste.

These materials are chosen based on factors such as durability, visibility, environmental impact, and cost-effectiveness, ensuring that utility markings remain effective and reliable in various conditions.

How long do utility marking products last in outdoor conditions?

Utility marking products, such as paints and tapes, are designed to indicate the presence of underground utilities like gas, water, and electrical lines. The longevity of these products in outdoor conditions depends on several factors, including the type of product used, environmental conditions, and the surface to which they are applied.

1. **Paints**: Utility marking paints are typically formulated to be temporary, lasting anywhere from a few weeks to several months. Water-based paints may last 1-3 months, while solvent-based paints can endure for 3-6 months. Factors such as UV exposure, rain, foot traffic, and temperature fluctuations can accelerate fading and wear.

2. **Tapes**: Marking tapes, often used for longer-term applications, can last from several months to a few years. They are more durable than paints and are resistant to weather conditions, but their longevity can still be affected by UV exposure, moisture, and physical abrasion.

3. **Environmental Conditions**: Harsh weather conditions, such as heavy rain, snow, and extreme temperatures, can significantly reduce the lifespan of both paints and tapes. In areas with high UV exposure, colors may fade more quickly.

4. **Surface Conditions**: The type of surface (e.g., asphalt, concrete, grass) also impacts durability. Smooth, non-porous surfaces may allow for longer-lasting markings compared to rough or porous surfaces, which can absorb the product and cause it to degrade faster.

In summary, utility marking products can last from a few weeks to several years, depending on the type of product, environmental conditions, and surface characteristics. Regular maintenance and reapplication may be necessary to ensure visibility and effectiveness.

Are there regulations or standards for utility marking products?

Yes, there are regulations and standards for utility marking products. These standards ensure the safety and consistency of marking underground utilities to prevent damage during excavation activities. In the United States, the American Public Works Association (APWA) has established a color code system for marking different types of utilities, which is widely adopted. The colors are as follows:

- Red for electric power lines, cables, conduit, and lighting cables

- Yellow for gas, oil, steam, petroleum, or gaseous materials

- Orange for communication, alarm, or signal lines, cables, or conduit

- Blue for potable water

- Purple for reclaimed water, irrigation, and slurry lines

- Green for sewers and drain lines

- Pink for temporary survey markings

- White for proposed excavation

Additionally, the Common Ground Alliance (CGA) promotes best practices for utility marking, including the use of these color codes. The Occupational Safety and Health Administration (OSHA) also provides guidelines to ensure safe excavation practices, which include proper utility marking.

In Europe, the European Committee for Standardization (CEN) has developed standards like EN 12889 for the identification of buried utilities. These standards are designed to harmonize practices across member countries.

Utility marking products themselves, such as flags, paints, and tapes, must comply with these standards to ensure visibility, durability, and environmental safety. Manufacturers often adhere to additional industry-specific standards to meet the needs of different regions and sectors.

Overall, these regulations and standards are crucial for preventing accidents, ensuring public safety, and maintaining the integrity of utility services during construction and excavation activities.