Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Safety

- Fall Protection

- Guardrails Gates Warning Lines For Fall Prevention

.....Read More

Frequently Asked Questions

What are the different types of passive fall protection systems?

Passive fall protection systems are designed to prevent falls without requiring active involvement from the worker. The main types include:

1. **Guardrails**: These are barriers installed at the edge of elevated surfaces to prevent falls. They typically consist of a top rail, mid-rail, and toe board, providing a physical barrier to protect workers.

2. **Safety Nets**: Installed below a work area, safety nets catch workers if they fall. They are commonly used in construction sites where guardrails are impractical.

3. **Warning Line Systems**: These are temporary barriers set up to alert workers of an approaching fall hazard. They are often used on flat roofs and consist of ropes, wires, or chains supported by stanchions.

4. **Parapet Walls**: These are extensions of the wall at the edge of a roof, providing a barrier to prevent falls. They are a permanent solution and part of the building's structure.

5. **Skylight Screens**: These are protective covers installed over skylights to prevent falls through them. They are designed to withstand the weight of a person.

6. **Floor Covers**: These are used to cover holes or openings in floors to prevent falls. They must be strong enough to support the weight of workers and equipment.

7. **Barricades**: Temporary or permanent barriers that restrict access to hazardous areas, preventing falls by keeping workers away from the edge.

These systems are essential for ensuring safety in workplaces with fall hazards, as they do not rely on worker behavior or require personal protective equipment.

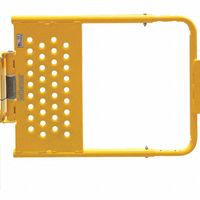

How do self-closing gates work in a guardrail system?

Self-closing gates in a guardrail system function as a safety mechanism to automatically close and secure an opening, ensuring continuous protection without manual intervention. These gates are typically installed at entry and exit points of guardrail systems, such as on elevated platforms, stairways, or mezzanines, to prevent accidental falls.

The operation of self-closing gates relies on a combination of mechanical components designed to ensure the gate returns to a closed position after being opened. Key components include:

1. **Hinges with Spring Mechanism**: The gate is mounted on hinges equipped with a spring mechanism. When the gate is opened, the tension in the spring increases. Once released, the stored energy in the spring forces the gate to swing back to its closed position.

2. **Adjustable Tension**: Many self-closing gates allow for the adjustment of spring tension. This feature enables customization of the closing speed and force, ensuring the gate closes securely without slamming, which could cause damage or injury.

3. **Latch System**: To ensure the gate remains closed, a latch system is often integrated. This can be a simple gravity latch or a more complex magnetic or mechanical latch that engages automatically when the gate returns to the closed position.

4. **Durable Materials**: Self-closing gates are constructed from robust materials like steel or aluminum to withstand environmental conditions and frequent use, ensuring long-term reliability and safety.

5. **Compliance with Safety Standards**: These gates are designed to meet specific safety standards and regulations, such as OSHA requirements, ensuring they provide adequate protection in industrial and construction settings.

By automatically closing and securing the opening, self-closing gates maintain the integrity of the guardrail system, reducing the risk of falls and enhancing overall workplace safety.

What are the benefits of using modular pipe guardrail systems?

Modular pipe guardrail systems offer several benefits:

1. **Flexibility and Customization**: These systems can be easily configured to fit various layouts and requirements. Components can be added, removed, or adjusted to accommodate changes in the environment or design specifications.

2. **Ease of Installation**: Modular systems are designed for quick assembly, often requiring minimal tools and labor. This reduces installation time and costs compared to traditional welded systems.

3. **Cost-Effectiveness**: The modular nature allows for efficient use of materials, reducing waste. Additionally, the ease of installation and potential for reconfiguration can lead to long-term savings.

4. **Durability and Strength**: Made from robust materials like steel or aluminum, modular pipe guardrails provide strong protection against impacts and are resistant to environmental factors such as corrosion.

5. **Safety Compliance**: These systems are designed to meet industry safety standards, ensuring that they provide adequate protection for workers and equipment in industrial and commercial settings.

6. **Maintenance and Repair**: Individual components can be replaced without dismantling the entire system, simplifying maintenance and reducing downtime.

7. **Aesthetic Appeal**: Modular systems offer a clean, professional look that can be tailored to match the aesthetic of the surrounding environment.

8. **Reusability and Sustainability**: Components can be reused in different configurations or locations, promoting sustainability and reducing the need for new materials.

9. **Scalability**: As needs change, modular systems can be expanded or reduced in size, providing a scalable solution that adapts to the growth or downsizing of a facility.

10. **Reduced Disruption**: Installation and modifications can often be completed with minimal disruption to ongoing operations, maintaining productivity and safety.

How do roof hatch guardrails enhance safety?

Roof hatch guardrails enhance safety by providing a physical barrier around roof access points, preventing accidental falls. These guardrails are crucial in ensuring that individuals accessing rooftops for maintenance, inspection, or other tasks are protected from the risk of falling, which is one of the leading causes of workplace injuries and fatalities in construction and maintenance industries.

Firstly, roof hatch guardrails create a defined perimeter around the hatch opening, making it immediately visible and alerting individuals to the potential hazard. This visibility is particularly important in low-light conditions or during inclement weather when the risk of missteps increases.

Secondly, the guardrails offer support and stability for workers as they transition between the roof and the hatch. This is especially beneficial when carrying tools or equipment, as it allows workers to maintain balance and reduces the likelihood of slips or falls.

Additionally, roof hatch guardrails are often designed to comply with safety regulations and standards, such as those set by the Occupational Safety and Health Administration (OSHA) in the United States. Compliance with these standards ensures that the guardrails are constructed to withstand specific forces and provide adequate protection.

Moreover, the presence of guardrails can reduce liability for building owners and employers by demonstrating a commitment to safety and adherence to regulatory requirements. This can lead to lower insurance premiums and reduced risk of legal action in the event of an accident.

In summary, roof hatch guardrails are a critical safety feature that protect workers from falls, provide stability during roof access, ensure compliance with safety standards, and reduce liability for building owners and employers.

What is the purpose of safety netting in construction sites?

The purpose of safety netting in construction sites is to enhance worker safety and prevent injuries or fatalities from falls, which are among the most common hazards in the construction industry. Safety nets serve as a fall arrest system, providing a crucial layer of protection for workers operating at heights. They are strategically installed below high work areas to catch workers if they fall, thereby reducing the risk of serious injury or death.

Safety nets also protect workers and the public from falling debris, tools, or materials, which can cause significant harm. By catching these objects, safety nets help maintain a safer environment both on the construction site and in surrounding areas.

Additionally, safety nets contribute to compliance with occupational safety regulations and standards, such as those set by the Occupational Safety and Health Administration (OSHA) in the United States. These regulations often mandate the use of fall protection systems, including safety nets, to ensure a safe working environment.

Furthermore, safety nets can enhance productivity by allowing workers to operate more confidently at heights, knowing that there is a safety measure in place. This can lead to more efficient work processes and potentially reduce project timelines.

In summary, safety netting in construction sites is essential for fall protection, debris containment, regulatory compliance, and improved worker confidence and productivity.

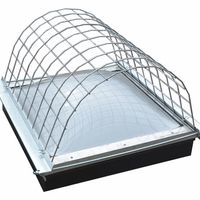

How do skylight guards prevent fall hazards?

Skylight guards prevent fall hazards by providing a physical barrier over or around skylights, which are often located on rooftops and can pose significant risks to workers. These guards are typically made from durable materials such as steel or aluminum and are designed to withstand the weight of a person, thereby preventing accidental falls through the skylight.

The primary function of skylight guards is to cover the fragile glass or plastic of the skylight, which is not designed to support the weight of a person. By installing a guard, the risk of someone stepping or falling onto the skylight and breaking through is significantly reduced. This is crucial in industrial and commercial settings where maintenance workers, roofers, or other personnel may be required to work on rooftops.

Skylight guards can be installed in various forms, including screens, cages, or railings, each tailored to fit the specific dimensions and design of the skylight. These guards are often secured to the roof structure, ensuring stability and reliability. Some designs are non-penetrating, meaning they do not require drilling into the roof, which helps maintain the roof's integrity and prevents potential leaks.

In addition to providing a physical barrier, skylight guards also serve as a visual warning, alerting workers to the presence of a skylight. This is particularly important in low-light conditions or when the skylight is covered by snow or debris, making it less visible.

Overall, skylight guards are a critical component of rooftop safety systems, helping to comply with occupational safety regulations and reducing the risk of serious injuries or fatalities from falls.

What are the regulations for installing warning lines on construction sites?

Warning lines on construction sites are regulated primarily by the Occupational Safety and Health Administration (OSHA) in the United States. According to OSHA standards, particularly 29 CFR 1926.502(f), warning lines are used as a fall protection measure in roofing work and other construction activities. Here are the key regulations:

1. **Height and Placement**: Warning lines must be erected around all sides of the roof work area. They should be at least 6 feet from the roof edge for roofing work and 15 feet for other construction activities. The lines must be between 34 and 39 inches above the walking/working surface.

2. **Materials**: The lines should consist of ropes, wires, or chains, and must be flagged at intervals of 6 feet or less with high-visibility material. The line must have a minimum tensile strength of 500 pounds and be rigged to withstand a force of at least 16 pounds applied horizontally.

3. **Access Points**: Points of access, materials handling areas, and storage areas must be connected to the work area by a clear path formed by two warning lines. When these paths are not in use, a rope, wire, chain, or equivalent barrier must be placed across the path at the point where it intersects the warning line.

4. **Training**: Workers must be trained to recognize the warning line system and understand its purpose. They should be aware of the areas beyond the warning lines and the associated fall hazards.

5. **Monitoring**: A safety monitor must be present when warning lines are used as the sole means of fall protection. The monitor must be competent to recognize fall hazards and have authority to ensure safety compliance.

These regulations ensure that warning lines effectively serve as a visual and physical barrier to prevent falls and enhance safety on construction sites.