Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Safety

- Safety Storage

- Safety Cabinets

.....Read More

Frequently Asked Questions

What are safety cabinets used for?

Safety cabinets are specialized storage units designed to safely store hazardous materials, including flammable liquids, corrosive substances, and toxic chemicals. They are essential in laboratories, industrial settings, and any environment where hazardous materials are used or stored. The primary purpose of safety cabinets is to minimize the risk of fire, explosion, and chemical exposure, thereby protecting personnel, property, and the environment.

These cabinets are constructed from materials that are resistant to the chemicals they are intended to store, often featuring double-walled steel construction with insulating air space to prevent the spread of fire. They are equipped with self-closing doors, secure locking mechanisms, and ventilation systems to prevent the accumulation of hazardous vapors. Safety cabinets are also color-coded and labeled according to the type of materials they store, such as yellow for flammable liquids, blue for corrosives, and red for combustible materials, to ensure easy identification and compliance with safety regulations.

In addition to fire protection, safety cabinets help in organizing chemicals, reducing clutter, and ensuring that incompatible substances are stored separately to prevent dangerous reactions. They are designed to comply with various safety standards and regulations, such as those set by OSHA, NFPA, and other relevant authorities, ensuring that they provide adequate protection and meet legal requirements.

Overall, safety cabinets are a critical component of a comprehensive safety strategy in any facility handling hazardous materials, contributing to a safer working environment by mitigating risks associated with chemical storage and handling.

How do safety cabinets reduce fire risk?

Safety cabinets reduce fire risk by providing a secure and controlled environment for storing flammable and hazardous materials. They are constructed from fire-resistant materials, such as double-walled steel with insulating air space, which helps to contain and delay the spread of fire. The cabinets are designed to maintain their structural integrity under high temperatures, preventing the contents from igniting.

The doors of safety cabinets are equipped with self-closing mechanisms and secure latches, ensuring that they remain closed in the event of a fire. This feature minimizes the exposure of flammable materials to heat and flames. Additionally, the cabinets often have a three-point locking system to prevent unauthorized access, reducing the risk of accidental spills or misuse of hazardous substances.

Ventilation systems in safety cabinets help to dissipate any vapors that may accumulate, reducing the risk of ignition from static electricity or other sources. The cabinets are also designed with built-in grounding connectors to prevent static discharge.

Safety cabinets are color-coded and labeled according to the type of materials they store, such as flammable liquids, corrosives, or pesticides. This labeling ensures that materials are stored correctly and that emergency responders can quickly identify the contents in case of a fire.

By organizing and segregating hazardous materials, safety cabinets prevent incompatible substances from coming into contact, which could lead to dangerous chemical reactions. They also help facilities comply with safety regulations and standards, reducing the likelihood of fines and enhancing overall workplace safety.

In summary, safety cabinets mitigate fire risk by containing flammable materials, preventing unauthorized access, providing ventilation, and ensuring proper storage and organization, all of which contribute to a safer working environment.

What are the color codes for safety cabinets?

Safety cabinets are color-coded to indicate the type of materials they store and the associated hazards. Here are the common color codes:

1. **Yellow**: Used for flammable liquids. These cabinets are designed to store substances that can easily ignite and are often labeled with "Flammable – Keep Fire Away."

2. **Red**: Indicates storage for combustible liquids. These are less volatile than flammable liquids but still pose a fire risk.

3. **Blue**: Designated for corrosive substances, such as acids and bases. These cabinets are often labeled with "Corrosive" to warn of the potential for chemical burns or damage.

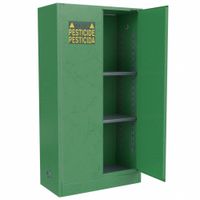

4. **Green**: Used for the storage of pesticides and other agricultural chemicals. These cabinets help prevent contamination and accidental exposure.

5. **White or Gray**: Typically used for storing poisons or toxic substances. These cabinets are marked to indicate the presence of materials that can cause harm if ingested or inhaled.

6. **Orange**: Reserved for the storage of biohazardous materials. These cabinets are used in laboratories and medical facilities to store materials that pose a biological risk.

7. **Black or White with Red Lettering**: Used for the storage of oxidizers. These substances can cause or enhance the combustion of other materials.

8. **Purple or White with Purple Lettering**: Designated for radioactive materials. These cabinets are used in facilities that handle radioactive substances to ensure safe storage and handling.

These color codes help ensure that materials are stored safely and that personnel can quickly identify the type of hazard present.

Are safety cabinets required by law?

Safety cabinets are often required by law, depending on the jurisdiction and the specific materials being stored. Regulations can vary widely, but generally, safety cabinets are mandated for the storage of flammable, combustible, or hazardous materials to minimize risks associated with fire, spills, and exposure.

In the United States, the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) provide guidelines and standards for the storage of hazardous materials. OSHA's regulations, particularly under 29 CFR 1910.106, outline requirements for the storage of flammable and combustible liquids, often necessitating the use of safety cabinets. The NFPA's standards, such as NFPA 30, also provide detailed requirements for the safe storage of flammable and combustible liquids, which typically include the use of safety cabinets.

In the European Union, the Classification, Labelling and Packaging (CLP) Regulation and the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) Regulation may influence the need for safety cabinets. Additionally, specific countries within the EU may have their own regulations that require the use of safety cabinets for certain hazardous materials.

In other regions, local laws and regulations will dictate the necessity of safety cabinets. For instance, in Canada, the Canadian Centre for Occupational Health and Safety (CCOHS) provides guidelines that often align with OSHA and NFPA standards.

Ultimately, whether safety cabinets are required by law depends on the type of materials being stored, the quantity, and the specific legal requirements of the jurisdiction. It is crucial for organizations to consult local regulations and standards to ensure compliance and maintain a safe working environment.

How should chemicals be organized in a safety cabinet?

Chemicals in a safety cabinet should be organized based on compatibility, hazard class, and proper labeling to ensure safety and prevent dangerous reactions. Here’s a detailed approach:

1. **Segregation by Hazard Class**:

- **Flammables**: Store in a dedicated flammable storage cabinet, away from oxidizers and sources of ignition.

- **Corrosives**: Separate acids from bases. Use corrosion-resistant shelving and secondary containment.

- **Oxidizers**: Keep away from flammables, combustibles, and reducing agents.

- **Toxics and Poisons**: Store in a secure, well-ventilated area, away from food and drink.

- **Reactives**: Isolate from other chemicals and store in a cool, dry place.

2. **Compatibility**:

- Use a chemical compatibility chart to ensure incompatible chemicals are not stored together. For example, acids should not be stored with cyanides or sulfides to prevent the release of toxic gases.

3. **Labeling and Identification**:

- Ensure all containers are clearly labeled with the chemical name, concentration, and hazard symbols. Use color-coded labels for quick identification.

4. **Shelving and Containment**:

- Use sturdy, chemical-resistant shelving. Store heavier containers on lower shelves to prevent tipping. Use secondary containment like trays to catch spills.

5. **Ventilation**:

- Ensure the cabinet is well-ventilated, especially for volatile chemicals, to prevent the buildup of fumes.

6. **Access and Security**:

- Limit access to authorized personnel only. Keep the cabinet locked when not in use.

7. **Inventory Management**:

- Maintain an up-to-date inventory and regularly check for expired or degraded chemicals.

8. **Emergency Preparedness**:

- Ensure safety equipment like eyewash stations and spill kits are nearby. Display emergency contact information and procedures clearly.

By following these guidelines, you can minimize risks and ensure a safe working environment.

What materials are safety cabinets made from?

Safety cabinets are typically constructed from materials that provide fire resistance, chemical resistance, and structural integrity. The primary materials used include:

1. **Steel**: Most safety cabinets are made from double-walled steel with an insulating air space between the walls. This construction provides fire resistance and durability. The steel is often powder-coated to enhance chemical resistance and prevent corrosion.

2. **Polyethylene**: For storing corrosive substances like acids and bases, cabinets made from high-density polyethylene (HDPE) are used. Polyethylene is highly resistant to chemical corrosion and is non-reactive with most acids and bases.

3. **Stainless Steel**: In environments where both fire resistance and chemical resistance are required, stainless steel may be used. It offers excellent resistance to corrosion and can withstand high temperatures.

4. **Wood**: Some safety cabinets, particularly those used for flammable liquids, may be constructed from wood. These are typically made from plywood with a fire-retardant coating. Wood cabinets are less common but can be used in specific applications where metal cabinets are not suitable.

5. **Fiberglass-Reinforced Plastic (FRP)**: This material is used for cabinets that need to withstand harsh chemical environments. FRP offers excellent chemical resistance and is non-conductive, making it suitable for certain applications.

6. **Aluminum**: Although less common, aluminum may be used for its lightweight properties and resistance to corrosion. However, it is not as fire-resistant as steel.

Safety cabinets are designed to meet specific regulatory standards, such as those set by OSHA, NFPA, and FM Global, ensuring they provide adequate protection for the materials stored within.

How do you maintain a safety cabinet?

To maintain a safety cabinet effectively, follow these steps:

1. **Regular Inspection**: Conduct routine checks to ensure the cabinet is in good condition. Look for signs of wear, corrosion, or damage.

2. **Cleanliness**: Keep the cabinet clean and free from spills. Use appropriate cleaning agents that do not react with stored chemicals.

3. **Ventilation**: Ensure proper ventilation to prevent the buildup of hazardous fumes. Check that vents are unobstructed and functioning.

4. **Labeling**: Clearly label all stored materials with their names, hazards, and handling instructions. Update labels as needed.

5. **Organization**: Arrange chemicals by compatibility to prevent dangerous reactions. Use shelves and dividers to separate different types of substances.

6. **Inventory Management**: Keep an updated inventory of all items stored in the cabinet. Regularly review and dispose of expired or unnecessary chemicals following proper disposal guidelines.

7. **Security**: Ensure the cabinet is locked when not in use to prevent unauthorized access. Only trained personnel should have access.

8. **Spill Containment**: Equip the cabinet with spill trays or absorbent materials to manage leaks or spills promptly.

9. **Fire Safety**: If storing flammable materials, ensure the cabinet is fire-resistant and located away from ignition sources. Check that fire suppression systems are in place and functional.

10. **Training**: Provide training for personnel on the proper use and maintenance of the safety cabinet, including emergency procedures.

11. **Documentation**: Maintain records of inspections, maintenance activities, and any incidents. This documentation is crucial for compliance and safety audits.

By adhering to these practices, you can ensure the safety cabinet remains a secure and effective storage solution for hazardous materials.