- Home

- Safety

- Safety Storage

- Safety Cabinets

- Safety Cabinet Locker Accessories

.....Read More

Safety Cabinet Hardware

Safety Cabinet Labels

Safety Cabinet & Locker Drum Rollers & Cradles

Safety Cabinet & Locker Filters

Safety Cabinet & Locker Ramps

Safety Cabinet & Locker Shelves, Dividers & Trays

Safety Cabinet & Locker Touch-Up Paints

Safety Cabinet Slope Covers

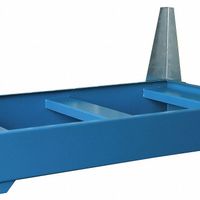

Safety Cabinet Spill Containment Sumps

Safety Cabinet Vent Plugs & Replacement Vent Assemblies

Safety Cabinet Wheels & Dollies

Frequently Asked Questions

What are the benefits of using safety cabinet and locker accessories?

How do sloped covers improve safety in storage areas?

What is the purpose of spill containment sumps under cabinets?

How do ramps assist in moving heavy containers in and out of cabinets?

What materials are commonly used for safety cabinet accessories?

How do I choose the right accessories for my safety cabinets?

Are there specific regulations for using safety cabinet and locker accessories?